In either case the soil used for backfill behind the sheet pile wall is usually granular.

Low wall sheet piling.

Wherever a wall or siding needs to be held back steel sheets are wedged into the earth at predetermined intervals.

Steel sheet piling steel sheet piles are long structural sections with a vertical interlocking system that create a continuous wall.

Let s take a look at how sheet piling works safety and driving factors and the types of retaining walls that can be used.

The surface of soil on the water side is referred to as the mud line or dredge line.

The ability of a sheet pile section to perform is dependent upon its geometry and the soils it is driven into.

The main advantage of vinyl sheet piles is the superior corrosion resistance when exposed to seawater where no oxidation occurs.

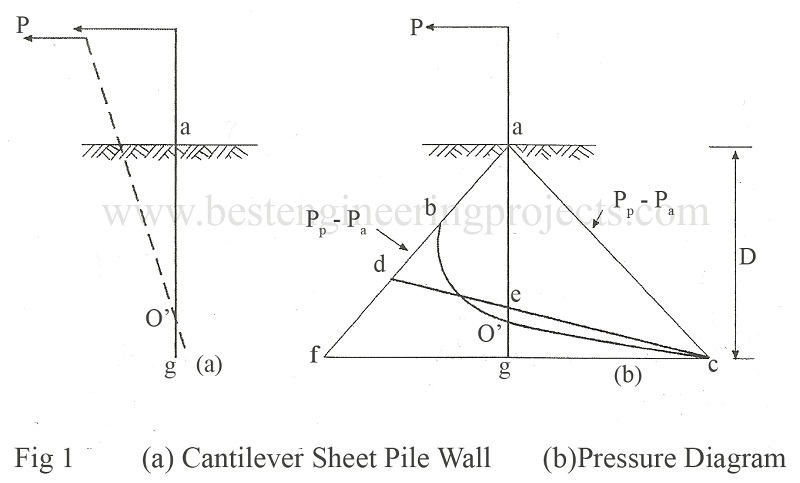

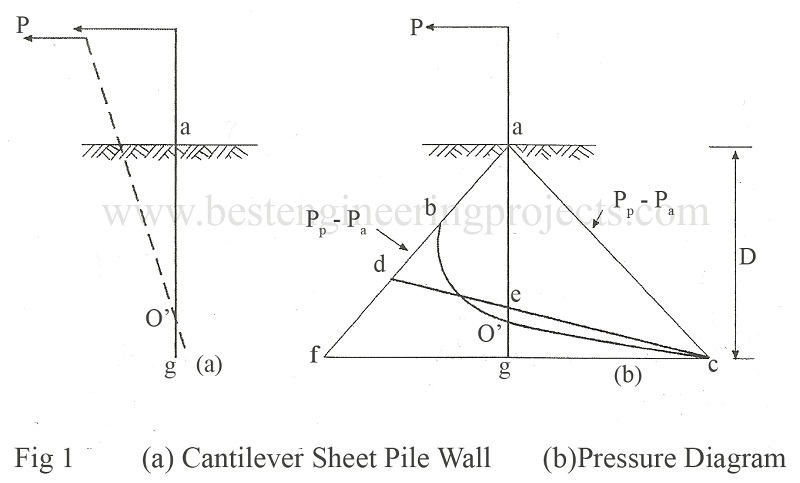

The term sheet piling refers to any retaining wall type that is a installed into the ground by driving or pushing rather than pouring or injection and b is of relatively thin cross section and low weight so that the weight of the wall does not assist in the wall s stability.

The walls are often used to retain either soil or water.

Thus construction methods generally can be divided into two categories sheet pile wall types.

We offer multiple brands and profiles of quality vinyl sheet piling and will assist you in choosing the profile that is right for your project and the property it is on.

Vinyl sheet piling or pvc sheet piles are an effective alternative to steel sheet piling for bulkheads seawalls and cutoff walls.

Our vinyl sheet piling will give your bulkhead or retaining wall unmatched longevity strength and erosion protection.

The term sheet piling refers to any retaining wall type that is a installed into the ground by driving or pushing rather than pouring or injection and b is of relatively thin cross section and low weight so that the weight of the wall does not assist in the wall s stability.

They are also superior to alternative materials like concrete and wood.